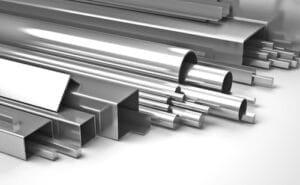

Stainless steel is a versatile steel alloy comprised of a percentage of chromium, which provides the material its corrosion resistance and the trait that gives stainless steel its name. There are many grades of stainless steel, but all must have a minimum chromium content of at least 10.5 percent and can range upwards of 20 percent depending on the application’s needs. The material is known for its excellent oxidation resistance, durability, and low maintenance, which is why it is widely used in producing a large and diverse array of parts and components in many industries. This makes understanding stainless steel tube fabrication an essential part of the purchasing process. (more…)

News

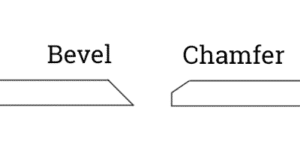

Bevel vs. Chamfer Edges: Differences and Applications Explored

Seamless vs. Welded Tubing: What’s the Difference?

Seamless vs. welded tubing represent two different types of stainless steel tubing used in various industrial and commercial construction, structural, medical, and aesthetic applications. Therefore, choosing between seamless vs. welded tubing will depend on the product application requirements. Though seamless and welded stainless steel tubing are common forms of tubing, they differ in a number of ways. Users should be aware of these primary differences, including the following: (more…)

Is All Stainless Steel Food Grade?

Is all stainless steel food grade? Certainly, stainless steel is a material of choice for various uses and applications in the food and beverage industry. From cutlery and countertops to walk-in refrigerators and transportation tankers, stainless steel meets specific requirements and standards deemed safe for food contact, processing, preparation, and storage. Nonetheless, though there are many grades of stainless steel, only a few in the 300 and 400 series have food-grade properties suitable for use in the food industry. We explain more below. (more…)

A Pocket Guide: Stainless Steel Specifications for Military Use

Following proper stainless steel specifications and guidelines are necessary to ensure the integrity of any application and fully function as designed, be it a fitting, fastener, or structural component, during the product’s intended service life. This is particularly important regarding applications manufactured for military use. Stainless steel is a material used widely in the defense and aerospace industries because, when correctly specified, it meets the operational requirements needed to perform in diverse environments and settings. (more…)